What is exothermic welding and why is it used?

Exothermic Welding (Exothermic Bonding) is an advanced method for creating permanent metal connections, particularly in grounding (earthing) systems, lightning protection, and industrial electrical connections. This technique uses a heat-generating chemical reaction to form a low-resistance, long-lasting bond, ensuring safe and durable connections in industrial and infrastructure projects.

Applications and Benefits of Exothermic Welding

Petunia’s exothermic welding is widely used in grounding systems, lightning protection, cathodic protection, and conductor connections. This method creates a permanent connection that is highly resistant to corrosion and heat while maintaining minimal electrical resistance, guaranteeing optimal performance of electrical systems and site safety. Key benefits include fast installation, minimal labor requirements, and long-term durability.

Petonia's services in the field of exothermic welding

With years of experience in electrical and grounding systems, Petunia provides comprehensive exothermic welding services, covering design, implementation, supervision, and final testing. Our services include:

1. Engineering & Design:

Identifying optimal points for exothermic connections, selecting appropriate materials and conductors, and calculating ideal electrical resistance according to international standards.

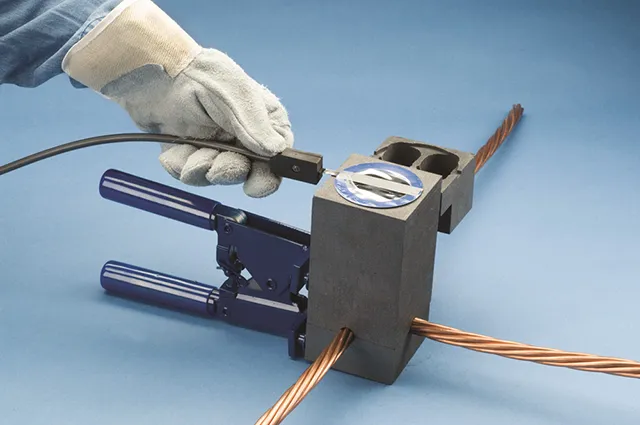

2. Professional Welding Execution:

Using advanced equipment and a specialized team to perform exothermic welds, ensuring strong, stable, and low-resistance connections in grounding and cathodic protection systems.

3. Supervision & Quality Control:

Careful monitoring of all implementation stages, checking electrical resistance, and verifying the accuracy and safety of welds before project delivery.

4. On-Site Inspection & Maintenance:

Providing periodic inspections, assessing the condition of connections, and maintaining systems to ensure longer lifespan and optimal performance of grounding and lightning protection systems.

This comprehensive approach ensures that your electrical systems operate with minimal resistance, maximum safety, and long-term reliability.

Why us?Why choose Petonia for implementing protective systems?

With over 30 years of experience in the electrical protection, earthing, and lightning protection industry, Petonia offers comprehensive and reliable solutions for industrial, construction, and infrastructure projects. The combination of precise engineering, modern equipment, and a specialist team has made our clients choose Petonia as their reliable partner in the field of earthing systems, lightning protection, and cathodic protection.

Experience and long-standing history

With over three decades of continuous operation, Petunia has unparalleled experience in the design and implementation of grounding systems, lightning protection, and cathodic protection. This history has enabled us to combine operational knowledge and expertise with international standards.

Comprehensive and integrated solution

From engineering and designing security systems to implementation, equipment installation, periodic testing and monitoring, all stages are carried out by the specialized Petonia team. This integrated approach reduces errors, increases safety, and optimizes system performance.

Specialized and professional team

Petunia executes every project with a team of experienced engineers, supervisors, and technicians with high precision in accordance with national and international standards. The team's practical experience in various industrial and construction projects ensures quality and safety.

Modern equipment and advanced technology

From engineering and design of protective systems to their execution, installation of equipment, periodic testing and monitoring, all stages are carried out by the specialized Petunia team. This integrated approach reduces errors, increases safety, and optimizes system performance.

Quality assurance and international standards

Petunia provides all services in accordance with IEC and IEEE standards, and technical reports and documented minutes are provided for each stage. This ensures customers of the correct performance and safety of the project.

Support and after-execution services

Petunia does not just complete the project; periodic monitoring, testing, and maintenance services ensure your protective systems always remain in ideal conditions.

Stages of implementing the exothermic welding project by Petunia

Petunia executes all combustion welding projects with precise engineering and international standards. Our process includes several key stages, each carried out with precision, expertise, and advanced equipment:

Engineering and Planning

Field visit and site preparation

Supervision and quality control during execution

Implementation of exothermic welding

Final testing and project delivery

Regular inspection and maintenance

Exothermic welding equipment and products

Petunia uses standard and high-quality equipment and accessories for the implementation of protective systems and exothermic welding, ensuring complete safety and stable system performance. All our products are designed and manufactured according to international standards and include welding connections, welding molds and accessories, welding powder and accessories.

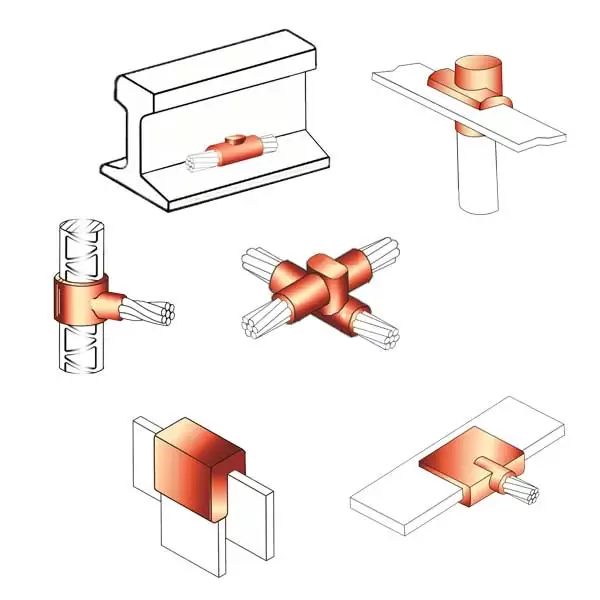

Exothermic welding connections

Standard and durable connections for creating stable electrical bonds in earthing and cathodic protection systems, with long-lasting performance and high reliability.

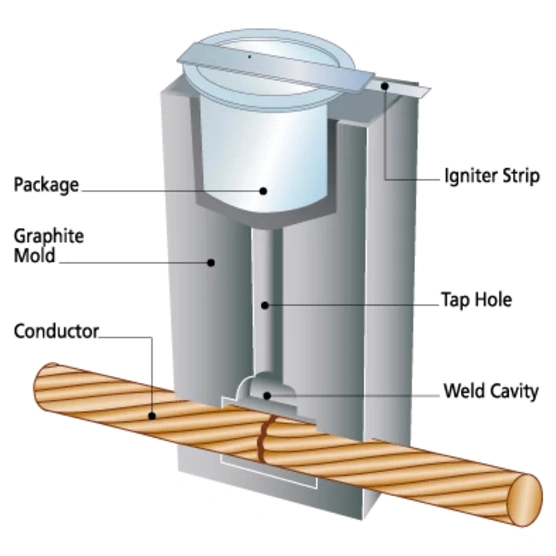

Welding mold and accessories

Specialized molds and accessories for the precise and safe execution of exothermic welding, ensuring the quality and durability of connections over time.

Welding powder and accessories

Welding powders with standard formulation and related equipment for creating resistant and low-resistance welds in protective and industrial earthing systems.

Exothermic Welding FAQ

Exothermic welding is a safe and durable method for connecting conductors in earthing systems, cathodic protection, and surge protectors. This method creates stable and long-lasting connections without the need for electrical current or external heat.

For performing exothermic welding, special powders, welding molds, and standard connectors are used that react with copper and steel conductors to create a strong and stable bond.

The main advantages include very high resistance, long lifespan, no need for complex equipment, rapid and safe execution, and reduced risk of incomplete connections or corrosion over time.

Yes, Petonia’s specialized team, in addition to supplying equipment, carries out the design, installation, and complete supervision of exothermic welding projects nationwide.

You can receive expert guidance and project cost estimates through the consultation request form on the site or by directly contacting Petonia’s experts.

Request for expert combustion welding consultation

Do you want to execute your earthing or cathodic protection project with safe and high-quality exothermic welding connections?

The Petunia expert team is ready to provide technical consultation, precise cost estimation, and step-by-step guidance for executing your project.

Request a consultation now and benefit from our professional experience!