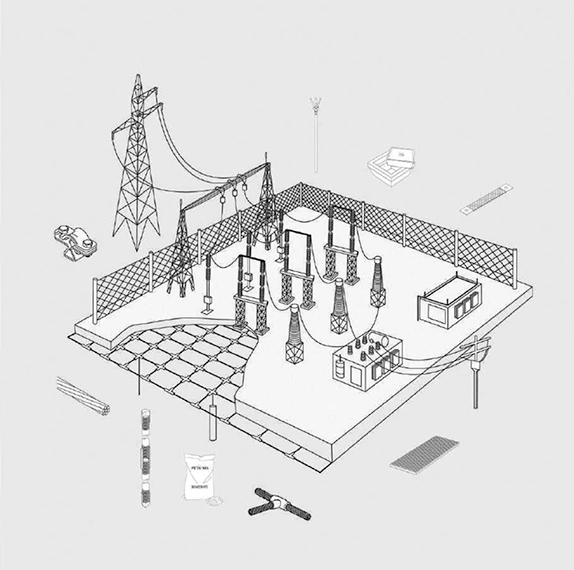

What is the grounding system and earthing pit, and its necessity?

Earthing System – Essential Protection for Electrical Installations

An Earthing System is one of the most critical components of any electrical installation, playing a key role in protecting people and equipment from electrical hazards. By safely directing fault currents, leakage currents, or lightning strikes to the ground, the system prevents electric shocks, fires, and equipment damage.

In industrial and building environments, proper design and installation of earthing pits and grounding systems ensure the safe operation of electrical equipment and the stability of power networks. Using high-quality components and engineered designs reduces earth resistance and guarantees a safe path for electrical discharge.

Petunia, with over three decades of experience in designing and implementing earthing systems, provides comprehensive and specialized solutions for oil, gas, petrochemical, construction, and power plant industries — ensuring the highest level of electrical safety in all projects.

Petonia's services in designing, implementing, testing, and monitoring grounding systems

Petunia – Comprehensive Grounding (Earthing) Solutions

Petunia provides complete grounding solutions, from engineering design to installation, testing, and periodic monitoring — ensuring the safety and reliable performance of industrial, building, and infrastructure facilities. All services are executed according to international standards using calibrated equipment to maintain proper earth resistance and fault current discharge paths.

1. Engineering (Specialized Grounding System Design)

Accurate engineering design is the foundation of any safe grounding system. Petunia analyzes site conditions and performs specialized calculations to deliver designs fully compliant with international standards.

Engineering services include:

-

Input Analysis: Assessment of project requirements, equipment load, site layout, and potential hazards (lightning, leakage currents, system bonding).

-

Soil Studies & Resistivity Measurement: Soil resistivity measurements using Wenner or Schlumberger methods to determine electrode depth and quantity.

-

Engineering Calculations: Ground Potential Rise (GPR/EARTHING CALC) calculations, electrode layout, network design, electrode weight and spacing, and connection cables according to IEEE/IEC standards.

-

Component Selection & Specifications: Determination of electrode types, conductor materials, connection methods (exothermic welding or mechanical clamps), and corrosion protection.

-

Technical Documentation: Delivery of as-built drawings, calculation reports, Bill of Materials (BOM), and method statements.

2. Installation (Grounding System Implementation)

Professional installation is performed by Petunia’s experienced teams to ensure that the system operates exactly as predicted by engineering designs.

Installation services include:

-

Site Preparation: Marking electrode locations, preparing cable routes, and removing obstacles.

-

Electrode Installation: Drilling and placing rods/meshes, using appropriate backfill to reduce resistance.

-

Connections & Exothermic Welding: Executing connections with exothermic welding or high-standard mechanical joints to ensure long-term conductivity and stability.

-

Bonding & Equipment Connection: Installing bonds, bushings, and connections to panels and sensitive equipment to guarantee safe discharge paths.

-

Safety & Documentation: Following worksite safety protocols and recording installation steps for initial reports.

3. Supervision (Quality Management & On-Site Control)

Petunia’s technical supervision ensures precise installation according to design and standards, and any deviations are promptly corrected.

Supervision services include:

-

Continuous On-Site Inspections: Presence of technical supervisors during key phases to verify compliance with drawings and specifications.

-

Quality Control of Materials & Components: Checking electrodes, conductors, connections, and backfill materials before installation.

-

Connection & Welding Inspection: Verifying exothermic welds and electrical continuity.

-

Reporting & Certification: Preparing inspection reports, checklists, and technical approval for each stage.

-

Correction Management: Providing corrective action plans and supervising their execution if defects are found.

4. Field Visits, Testing & Monitoring (Earth Resistance Testing, Maintenance & Monitoring)

Periodic testing and monitoring ensure the grounding system maintains its performance over time. Petunia provides testing, calibration, and maintenance services.

Field visits, testing, and monitoring services include:

-

Post-Installation Testing: Measuring earth loop resistance and ground continuity immediately after installation.

-

Periodic Monitoring: Scheduled measurements (e.g., annually or per contract) of earth resistance, step & touch potential, and corrosion inspection.

-

Analog & Online Monitoring: Installing sensors and monitoring systems for real-time earth resistance tracking and alerts.

-

Reporting: Providing analytical reports with earth resistance trends and preventive maintenance recommendations.

-

Maintenance & Repairs: Electrode restoration, backfill replacement, connection reinforcement, and corrosion mitigation if necessary.

Why us?Why choose Petonia for implementing the grounding system or earthing pit?

With over 30 years of experience in the electrical protection and earthing industry, Petunia provides comprehensive and reliable solutions for industrial, building, and infrastructure projects. The combination of precise engineering, modern equipment, and a specialized team has led our clients to choose Petunia as a trusted partner in the field of earthing, lightning protection, and cathodic protection systems.

Experience and long history

With more than three decades of continuous activity, Petunia has unparalleled experience in the design and implementation of grounding, lightning protection, and cathodic protection systems. This history has allowed us to combine operational knowledge and expertise with international standards.

Comprehensive and integrated solution

From engineering and design of the grounding system to well execution, equipment installation, periodic testing and monitoring, all stages are carried out by Petunia's specialized team. This integrated approach reduces errors, increases safety, and optimizes system performance.

Specialist and professional team

Patunia with a team of experienced engineers, supervisors, and technicians executes every project with high precision, adhering to national and international standards. The team's practical experience in various industrial and construction projects ensures quality and safety.

Modern equipment and advanced technology

From system grounding engineering and design to well execution, equipment installation, periodic testing and monitoring, all steps are carried out by Petonia's specialized team. This integrated approach reduces errors, enhances safety, and optimizes system performance.

Quality assurance and international standards

Patonia provides all services in accordance with IEC and IEEE standards, and technical reports and documented minutes are provided for each stage. This ensures customers of the correct performance and safety of the project.

Support and after-execution services

Petonia not only completes the project; periodic monitoring, ground resistance testing, and maintenance services ensure your earthing system remains in optimal condition.

The stages of executing the earthing system project by Petonia

Patunia executes all grounding system projects with a precise engineering approach and international standards. Our work process includes four main stages, each carried out with precision, expertise, and advanced equipment:

Engineering and design of grounding system

Field visit and evaluation

Supervision and quality control

Implementation and execution of grounding

Equipment and products used in the grounding system

Petunia utilizes high-quality, standardized equipment and accessories for the implementation of grounding (earthing) systems, ensuring complete safety and reliable system performance.

All our products are designed and manufactured according to international standards and include grounding rods, earth resistance reducing materials, ground plates and discharge electrodes, busbars and grounding boxes, clamps and grounding system accessories, as well as testing and monitoring devices for grounding systems.

Ground electrode and accessories

The main component of the grounding system for discharging unwanted currents to the ground.

Ground electrical resistance reducing materials

Reduce ground resistance and improve the performance of the grounding system.

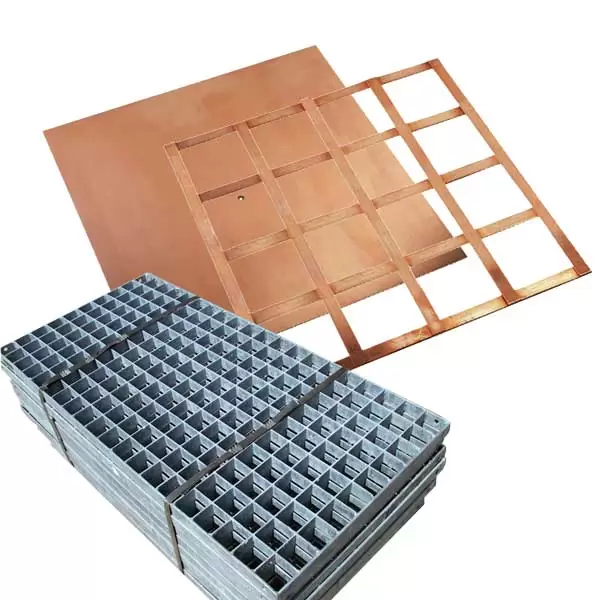

Ground plates and electrical discharge

Equipment for safely conducting electrical currents to the ground and discharging electrical charges, ensuring protection of structures and equipment against electrical hazards.

Earth busbars and earth boxes

Central connection systems and ground current distribution for complete safety of industrial electrical networks and buildings.

Earthing system clamps

Strong and resistant connections for attaching cables and grounding rods, ensuring stability and safe current transfer.

Grounding system accessories

Auxiliary parts and essential accessories for completing and maintaining the grounding system, including connections, clamps, and auxiliary equipment.

Earthing system devices

Specialized tools and equipment for measuring, testing, and monitoring the performance of earthing systems to ensure complete safety.

FAQFrequently Asked Questions about Earthing Systems

The earthing system is a set of equipment and wiring that directs dangerous electrical currents to the ground to prevent harm to people, equipment, and buildings. Proper earthing use ensures the safety of lives and protection of your assets.

The ground resistance is measured with earthing test devices. To reduce ground resistance, we use resistance-reducing materials, high-quality grounding rods, and proper design of the ground grid. The Petonia team optimizes all stages according to international standards.

The selection of grounding rods and accessories depends on the soil type, project area, and equipment voltage. Petunia, with its diverse range of products including grounding rods, busbars, clamps, and accessories, offers the best options tailored to your needs.

The grounding system should be tested and monitored at least once a year or after any modifications in the electrical installations. Regular inspection and maintenance ensure the correct performance and safety of the system.

Yes. The Petunia team provides engineering services, implementation, supervision, and periodic field visits to ensure your earthing system always remains up to standard and safe.

Request for specialized earthing consultation

Consultation on Design, Implementation, and Monitoring of Ground Protection Systems

Do you want to design and implement your earthing project with international standards? Petunia’s expert team is ready to provide technical advice, custom design, site review, and professional implementation of the earthing system.

To receive free consultation or to communicate your needs, fill out the form below or contact our experts.