What is cathodic protection and its applications

Cathodic Protection – Advanced Solutions for Metal Corrosion Prevention

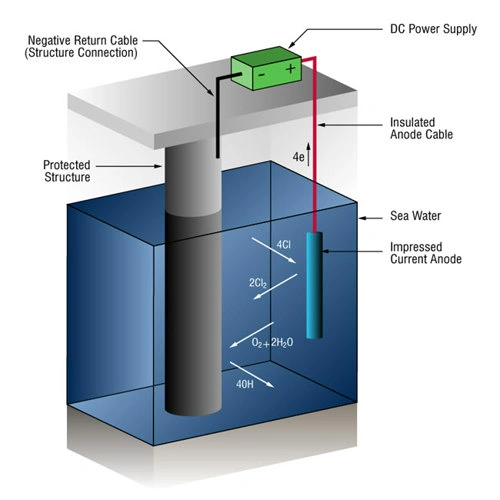

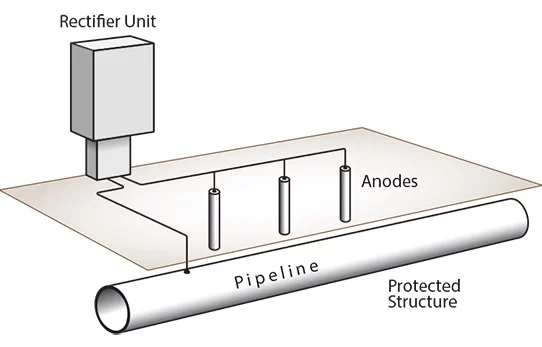

Cathodic protection is a specialized method for preventing metal corrosion in aggressive environments such as soil, water, and industrial tanks. By applying controlled electrical currents or connecting sacrificial metals, this system protects metal structures from deterioration and significantly extends their service life.

Applications of Cathodic Protection include:

- Protection of oil, gas, and water pipelines

- Protection of industrial tanks and storage vessels

- Safeguarding offshore structures and docks

- Protection of underground metal equipment and bridges

Petunia’s cathodic protection systems, utilizing advanced equipment and international standards, ensure that your metal assets are fully safeguarded against corrosion.

Petunia's services in the design, execution, testing, and monitoring of cathodic protection systems

With decades of experience in cathodic protection, Petunia provides comprehensive services for the design, implementation, testing, and monitoring of cathodic protection systems, ensuring that your metal structures are fully safeguarded against corrosion.

1. Engineering & Design of Cathodic Protection Systems:

Petunia’s expert team designs efficient and optimized cathodic protection systems based on project specifications, environmental conditions, and international standards. This includes determining anode installation points, calculating protective currents, and selecting appropriate equipment.

2. Implementation & Installation of Cathodic Protection Systems:

Petunia executes the installation with precision, from anode placement and wiring to correct connection with structures. Every step is carried out following strict safety and quality standards.

3. Supervision & Quality Control of Cathodic Protection Systems:

Throughout the project, Petunia engineers oversee the execution and installation quality to ensure the system operates correctly. This includes inspecting connections, performing initial tests, and adjusting protective currents.

4. On-Site Inspection & Continuous Monitoring of Cathodic Protection Systems:

After installation, Petunia provides periodic inspections and continuous monitoring to identify and resolve potential issues, ensuring the cathodic protection system always performs at its highest efficiency.

Why us?Why choose Petunia for the implementation of a cathodic protection system?

With over 30 years of experience in the electrical protection, earthing, and lightning protection industry, Petunia provides comprehensive and reliable solutions for industrial, construction, and infrastructure projects. The combination of precise engineering, modern equipment, and a specialist team has led our clients to choose Petunia as a reliable partner in the field of earthing systems, lightning arresters, and cathodic protection.

Extensive experience and history

With over three decades of continuous activity, Petunia has unparalleled experience in the design and implementation of earthing systems, lightning protection, and cathodic protection. This history has enabled us to integrate operational knowledge and expertise with international standards.

Comprehensive and integrated solution

From engineering and designing the cathodic protection system to its implementation, equipment installation, testing, and periodic monitoring, all stages are carried out by the specialized team at Petunia. This integrated approach reduces errors, increases safety, and optimizes system performance.

Specialized and professional team

Petonia executes each project with high precision and in accordance with national and international standards, with a team of experienced engineers, supervisors, and technicians. The team's practical experience in various industrial and construction projects ensures quality and safety.

Modern equipment and advanced technology

From cathodic protection system engineering and design to their implementation, equipment installation, testing, and periodic monitoring, all stages are carried out by Petonia's specialized team. This integrated approach reduces errors, enhances safety, and optimizes system performance.

Quality assurance and international standards

Petunia offers all services according to IEC and IEEE standards and provides technical reports and documented minutes for each stage. This ensures customers of the correct functioning and safety of the project.

Support and after-execution services

Petunia not only completes the project; periodic monitoring, testing, and maintenance services assure you that the cathodic protection system always remains in ideal conditions.

Project implementation stages of the cathodic protection system by Petunia

Petunia executes all cathodic protection system projects with precise engineering approaches and international standards. Our work process includes four main stages, each performed with precision, expertise, and advanced equipment:

Engineering and planning

Site visit and assessment

Supervision of installation and execution

Testing, monitoring, and commissioning of the cathodic protection system

Periodic inspection and maintenance of the cathodic system

Equipment and products used in cathodic protection systems

Petunia utilizes high-quality, standardized equipment and accessories for the implementation of cathodic protection systems, ensuring complete safety and reliable system performance.

All our products are designed and manufactured according to international standards and include rectifier transformers, anodes, cathodic protection junction boxes and markers, testing and measurement equipment, isolators, flange insulation kits, cables, and related accessories such as joints, clamps, and end caps.

Transformer Rectifier

The transformer rectifier plays the heart role of the cathodic protection system and provides the necessary direct current to prevent metal corrosion.

Anodes

Anodes act as a source of protective current and, with precise installation, enhance the lifespan of structures in corrosive environments.

Cathodic protection junction boxes and markers

These boxes are where cables and protective equipment are connected, and markers specify the location of anodes for inspection and maintenance.

Test and measurement equipment

These devices allow precise monitoring of the cathodic protection system and ensure the proper flow and protective coating function.

Separator equipment

Flow separation equipment is used to control and manage protective flow between structures and anodes, enhancing the safety of the system.

Flange insulation kit

Flange insulation kits protect metal connections from corrosion and optimize the performance of the cathodic protection system.

Cables used in cathodic protection systems

Cables used in cathodic protection systems are usually single-core and have XLPE/PVC insulation.

Cathodic protection accessories and ancillary items

This category includes essential connections such as joint, coke, hand cap, and other accessories that facilitate the installation and maintenance of the system.

FAQFrequently Asked Questions about Cathodic Protection Systems

Cathodic protection is an advanced method to prevent corrosion of metals such as pipes and tanks in corrosive environments. This system increases the lifespan of structures and reduces maintenance and repair costs.

This system stops corrosion reactions by supplying direct electrical current to metal structures, protecting the metals against corrosion.

The main equipment includes transformer rectifiers, anodes, junction boxes, markers, cables and related accessories, test and measurement equipment, and flange insulation kits.

To ensure proper functioning, the system should be inspected and measured at least once a year by a team of specialists. In highly corrosive environments, shorter inspection intervals are recommended.

Yes, the design, installation, and monitoring of this system require specialized engineers with experience in cathodic protection to ensure proper functioning and the longevity of the structure.

The benefits include extending the lifespan of structures, reducing maintenance costs, increased safety, and compliance with international standards.

Request for specialized cathodic protection consultation

The Petunia engineering team is ready to provide professional solutions for the design, installation, and monitoring of cathodic protection systems for your industrial and infrastructure projects.

Contact us now and get a free consultation!

To get a free consultation or to declare your needs, fill out the form below or contact our experts.